The Best Guide To Premier Aluminum Llc

The Best Guide To Premier Aluminum Llc

Blog Article

Premier Aluminum Llc Can Be Fun For Everyone

Table of Contents3 Easy Facts About Premier Aluminum Llc DescribedFascination About Premier Aluminum LlcThe smart Trick of Premier Aluminum Llc That Nobody is Talking AboutA Biased View of Premier Aluminum Llc

(https://www.mixcloud.com/premieraluminum/)Typically, a buyer's main obligation was to find certified and responsive distributors. In some cases, buyers presumed that any type of vendor ready to contractually satisfy the acquisition requirement was certified. Making use of reduced expense and unqualified vendors can cause quality issues, and wasted time and cash in the lengthy run. To assist you via the process, below are some points to take into consideration when choosing the ideal steel spreading supplier.

For instance, a firm that only makes use of the financial investment casting procedure will try to market you on why that process is best for your application. What if utilizing the sand spreading process is best for you and your demands? Instead, look for a provider that uses a variety of casting processes so the ideal alternative for YOU is picked

If dealing with a single source for all of your spreading needs is necessary to you, the vendor requires to be diverse in its abilities. When combined with various other incorporated capabilities, this can assist simplify and compress the supply base. When choosing the best casting vendor, careful factor to consider should be provided to high quality, solution, and price.

Excitement About Premier Aluminum Llc

Buyers increasingly select casting suppliers who have machining capabilities. If the casting provider discovers a concern throughout machining, the trouble is settled quicker with no conflict over whose mistake it is.

What do you require from your spreading vendor? Are you looking for somebody to just deliver a metal component to your front door or do you need extra?

Some shops are restricted or specialized. Make sure the supplier can meet check that all your material or alloy demands to get rid of the demand for numerous suppliers.

Premier Aluminum Llc - An Overview

Research the vendor's web site. Speak with a sales representative or business partner. Ask a great deal of questions. Visit their facility. Get an understanding of what they can do for you and if you can see yourself developing a solid, mutual relationship with them.

Light weight aluminum is also lightweight and has great rust resistance, making it ideal for applications where weight and sturdiness are vital aspects. Furthermore, light weight aluminum spreading is an affordable method of production, as it requires much less power and resources than various other techniques. Iron casting, on the various other hand, involves pouring liquified iron right into a mold to develop a preferred form.

8 Simple Techniques For Premier Aluminum Llc

Iron spreading is likewise able to hold up against heats, making it ideal for usage in applications such as engine parts and industrial machinery. Nonetheless, iron spreading can be much more expensive than aluminum spreading as a result of the higher expense of resources and the power needed to thaw the iron. When choosing between light weight aluminum casting and iron spreading, it is very important to take into consideration the details needs of the application.

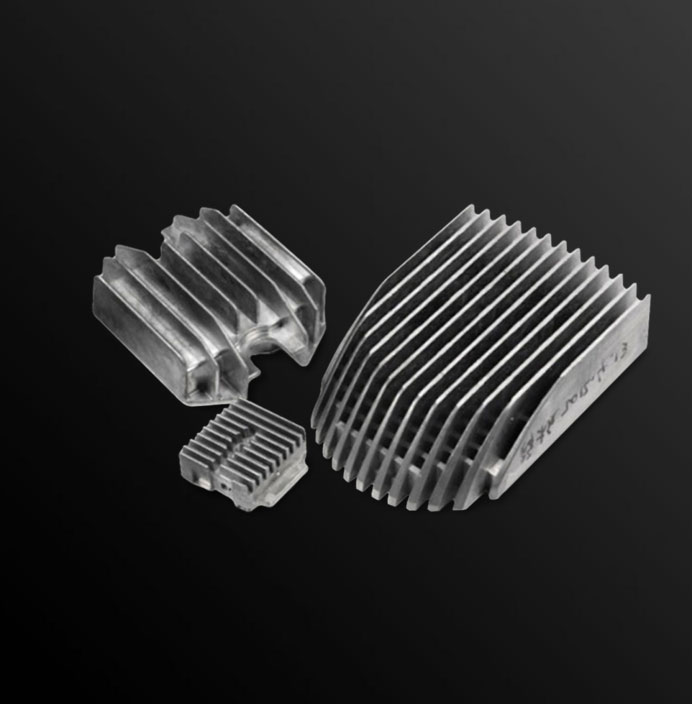

In verdict, both aluminum spreading and iron casting have their own one-of-a-kind benefits and negative aspects. There are 3 sub-processes that drop under the group of die casting: gravity die casting (or permanent mold and mildew spreading), low-pressure die casting and high-pressure die spreading. To get to the finished product, there are 3 key alloys made use of as die casting material to select from: zinc, light weight aluminum and magnesium. Report this page